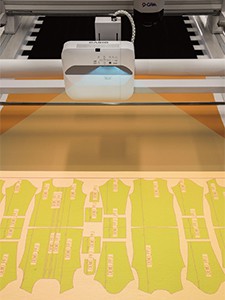

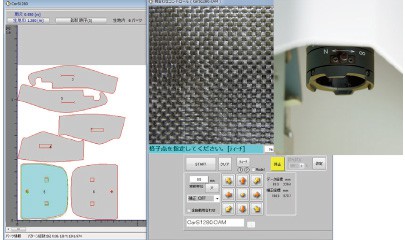

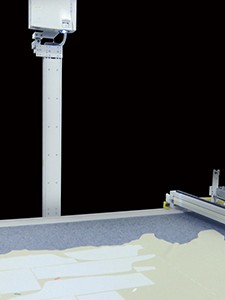

Highly Accurate Cutting

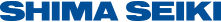

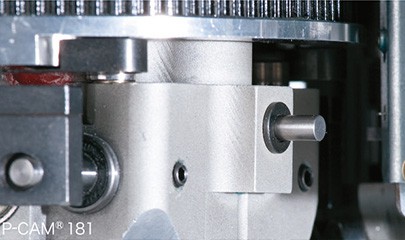

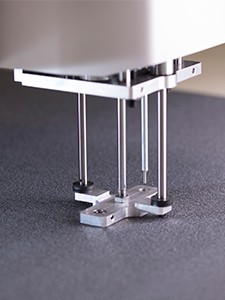

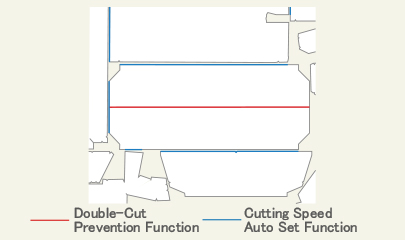

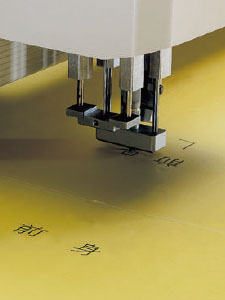

Cutting method is selectable among drag knife, reciprocating knife and ultrasonic knife. The drag knife can be replaced easily as a unit. Furthermore the reciprocating knife utilizes automatic knife sharpening for higher accuracy in cutting.