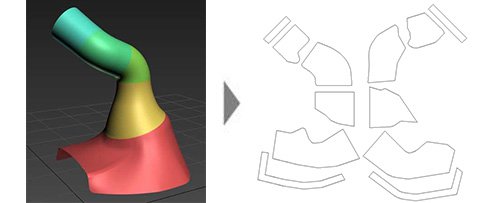

3D data can be generated, and patterns

can be created and edited from 3D data as well.

Winds of Change

— Industrial Materials —

SHIMA SEIKI design systems and software, computerized knitting machine and cutting machines

support production using various industrial materials in a wide range of appliations.

Safety

Cut-resistance

Thermal

insulation

Fireproofing

Noise

suppression

Soundproofing

Special

materials

Special forms

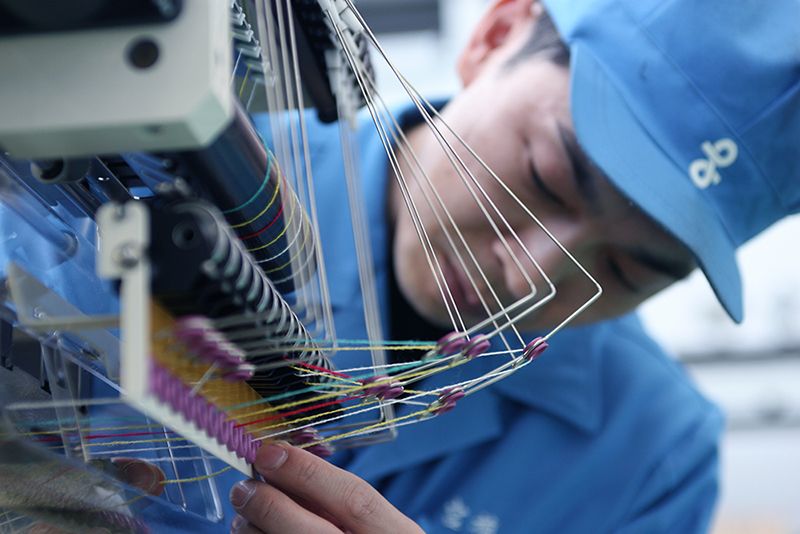

Knit It

Compared to woven fabrics, shaped knitting can produce

items to shape, shortening lead time significantly.

SHIMA SEIKI continues to develop technologies, for

knitting special materials such as carbon fiber, metal,

and monofilament.

Why knit with SHIMA SEIKI?

WHOLEGARMENT can produce items

in one entire piece three-dimensionally,

for shortened lead times and cost savings.

Design It

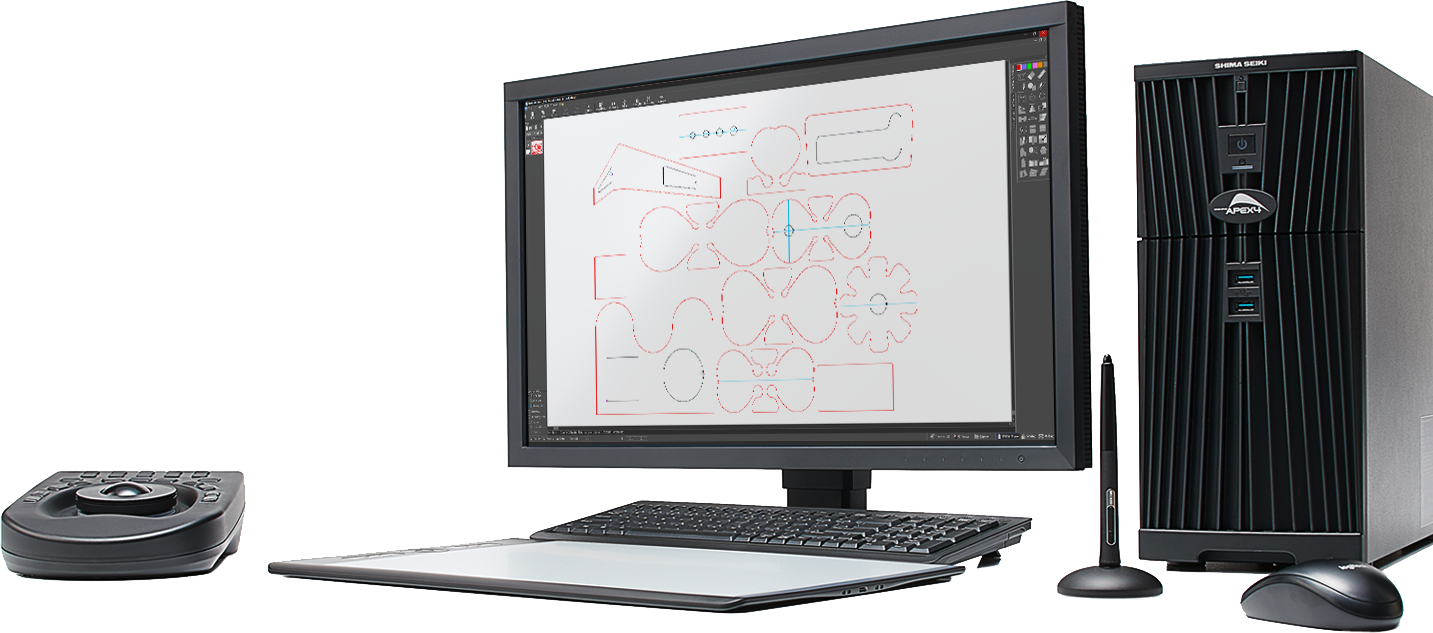

With the SDS-ONE APEX series design system

and software, designs can be evaluated

during the planning and design stages

using "virtual samples" created by simulations.

The need for sampling is eliminated

because it is realistic enough to be regarded

as an actual product, which can shorten

lead times for product development.

Furthermore, conversion from 3D data

to 2D pattern data is also possible,

and conversion to production machine data is easy.

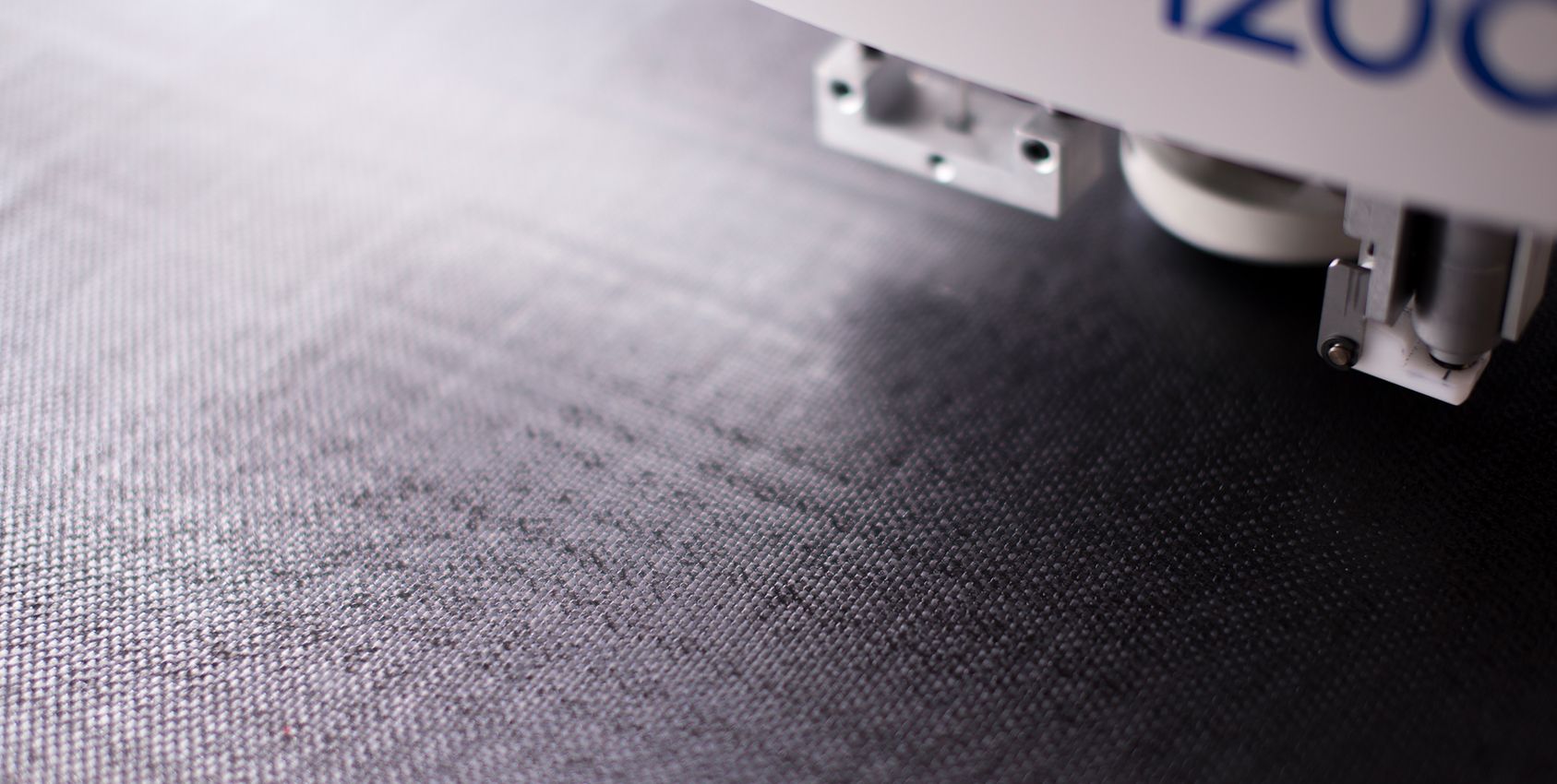

Cut It

Composite materials such as CFRP and

GFRP are gaining attention for their

light weight and strength.

SHIMA SEIKI NC cutting machines can

easily handle these materials as well as

a wide range of other industrial materials

including aramid fiber, polyethylene fiber,

and non-woven fabrics.

Benefits of SHIMA SEIKI's Cutting Machine

User Support by SHIMA SEIKI

Service & Maintenance

SHIMA SEIKI has established a user support system worldwide. Customers can use our products with reassurance from a comprehensive maintenance program, training programs suited to each customer's needs, and a steady, long-term supply of genuine parts.

The SHIMA SEIKI Online Services portal site is a one-stop source for accessing various web-based services.

From fashion information and SHIMA KnitManager™ to sample data downloads, FAQs and tutorials, we support our users in all stages of the product supply chain.

We can tailor solutions to fit each customer's requirements.

Please feel free to contact us.

TOP>Products>Select Business>Industrial Materials