Conserving limited resources

WHOLEGARMENT® knitwear is produced in one entire piece, consuming only the amount of yarn required for that item.

Dimensional shaping creates clean shoulder lines and produces a garment that conforms better to the shape of the body.

Seams no longer interfere with the continuity of the knit fabric from front to back. In addition, for garments with complex patterns using multiple pieces, 3D shaping using knitted-in darts creates a beautiful silhouette with flowing drape.

Knitted-in necklines and collars create a refined and sophisticated look.

No seams under the arms eliminates the bulky discomfort of typical sewn knitwear.

SHIMA SEIKI's 3D design system and software, combined with WHOLEGARMENT® flat knitting machines, achieve what could not be realized with conventional knit production.

Improve planning accuracy and efficiency through use of virtual samples

Enable presale events for forecasting demand

Minimize post-processing

and reduce lead time

Quick response supports mid-season production and customization.

Optimized inventory prevents leftover stock and avoids bargain pricing

Earth-friendly by using minimal resources

"Reshoring" of production to consumption areas

WHOLEGARMENT® knitwear is produced in one entire piece, consuming only the amount of yarn required for that item.

High-resolution virtual samples created on the SDS®-ONE APEX series design system and software are realistic enough to replace actual sampling that requires significant time, cost and material.

The combination of virtual sampling and WHOLEGARMENT® knitting can optimize inventory and minimize leftovers that otherwise go to waste.

With 3D knitting based on patterns, flared skirts and dresses with multiple pattern pieces can be knit without seams. Hem width can be adjusted using flechage or short-row technique for producing silhouettes exactly as intended. Bold and elegant drapes can be created as well.

Weaving specialty yarn through knitted fabric yields a unique product that blends the soft stretch of knits with the sophistication of wovens (Select WHOLEGARMENT® knitting machines can be fitted with the inlay carrier option for efficient inlay knitting).

WHOLEGARMENT® knitwear using inlay technique is surprisingly light and comfortable. Jackets, coats and suits that are traditionally woven can now be produced as knitwear. By knitting on its side, stretch in the horizontal direction is combined with non-stretch yarn in the vertical direction that helps Airdrobe maintain its shape.

For lace patterns and transparent designs, seams are inevitably noticeable. However when produced as a WHOLEGARMENT® item, the elegance of transparency itself can be enjoyed to its fullest.

WHOLEGARMENT® knitwear can perform changeovers in knit patterns, structures, textures and materials. Changeovers can also be performed for knitting-in special functional yarns in key positions for extra added-value. For example, moistureabsorbing, quick-dry material can be used under the arms, or soil-resistant yarns can be used at the collar and cuffs.

With better control over flechage, deeper necklines can be produced. New capabilities in WHOLEGARMENT® knitting allow new styles that help increase the attraction of knitwear.

Changing colors while using short-row technique yields designs that mimic intarsia patterns without sacrificing production efficiency.

Spring-type moveable sinkers allow for the production of dimensional fabric effects such as pintuck or ottoman stitches.

Flechage can be used to increase the amount of frill, ruffles and other details.

3D pants can be knitted with more fabric on the front of the legs to form a natural bend at the knees, as well as other measures to increase comfort and form a more attractive silhouette.

The refined capability of WHOLEGARMENT® knitting is most apparent in basic styles whose faults if any are difficult to hide.

WHOLEGARMENT® knitwear can be knit in low gauges as well, with coarse texture and a hand-knitted look.

Jacquard knits can be knit efficiently using two systems.

Pockets with flaps, hoods, plackets and buttonholes can be knitted-in without seams, ensuring consistent product quality and avoiding problems with labor shortage.

Reverse applications of half-cardigan stitch yield structures with volume. Efficiency is also ensured by using two systems.

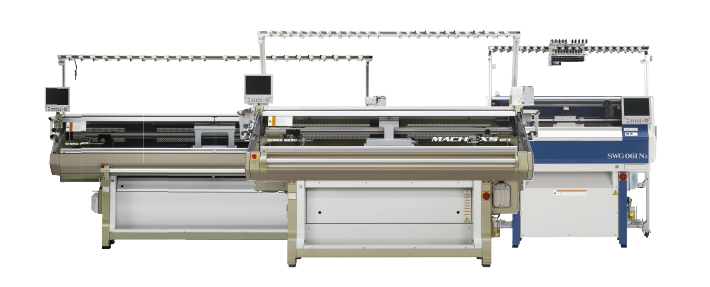

SHIMA SEIKI WHOLEGARMENT® knitting machines provide wide patterning range,

high efficiency and stable, consistent production of WHOLEGARMENT® products.

SHIMA SEIKI's WHOLEGARMENT® knitting machine lineup supports a variety of production needs.

In addition, there is growing interest in WHOLEGARMENT® knitting for applications outside the field of fashion, including interior furnishings, sports, medical, automotive, aerospace, and other industrial textiles. Of particular interest are the unique opportunities in technical textiles provided by WHOLEGARMENT® technology for knitting seam-free tubes and performing 3D shaping.

The SDS®-ONE APEX series design system and software can be used to create simulations that are realistic enough to be mistaken for the real thing. These simulations can be used as virtual samples that can replace actual sampling in the design evaluation phase.

In addition, virtual samples can be used for presale activities in-store or on EC sites for forecasting demand, allowing production volume to be controlled and inventory optimized for preventing leftover waste.

The WHOLEGARMENT® knitting machine was first introduced at the International Textile Machinery (ITMA) exhibition in 1995. Described as the “Magic of the Orient,” WHOLEGARMENT® knitting technology has undergone much progress since its introduction, in productivity and efficiency, flexibility, reliability, and expanded patterning capability as well as product range. The benefits of WHOLEGARMENT® now go far beyond what was originally expected from the simple elimination of seams. 30 years of innovation have prepared WHOLEGARMENT® to take on the demands of mainstream knit production in the 21st century.

From the moment the first glove fell through the chute of SHIMA SEIKIʼs original product, the fully automated glove knitting machine, founder Masahiro Shima was already inspired as to the direction the company would be taking into the 21st century. The hint was in the glove, itself a WHOLEGARMENT® product. Turning the glove upside-down and joining the middle-three fingers to form the body, with the pinky and thumb as the sleeves and the cuff portion as the collar, a tiny sweater is formed.

Since its introduction 30 years ago, WHOLEGARMENT® technology has been continually evolving.

WHOLEGARMENT® is the cutting edge in flat knitting technology, with an impressive number of patents.

WHOLEGARMENT® technology is recognized for its many achievements throughout the years.

With 30 years of experience in the development, manufacture and marketing of WHOLEGARMENT® knitting machines, we have firmly established an effective customer support program along the way. Now that WHOLEGARMENT® knitting is playing a greater role in global knit production, our commitment to customer support is greater than ever.

WHOLEGARMENT® product tags are available for use by knitting companies, apparel companies, designers and merchandisers associated with the production and promotion of WHOLEGARMENT® knitwear, identifying them at the retail level as genuine WHOLEGARMENT® products in order to distinguish them from conventional knitwear. Over 22 million WHOLEGARMENT® product tags have been sold to date (as of January 2025).

Showrooms at our Wakayama headquarters, Tokyo and Osaka branch offices, Milan, Los Angeles, Derbyshire, Seoul, Shanghai and Hong Kong always have the latest samples on display, and provide opportunities for strategic meetings among designer, apparel merchandiser, yarn spinner and knit manufacturer.

SHIMA SEIKI offers training courses for WHOLEGARMENT® technology at its headquarters in Japan, or at subsidiaries, branch offices and agencies worldwide.

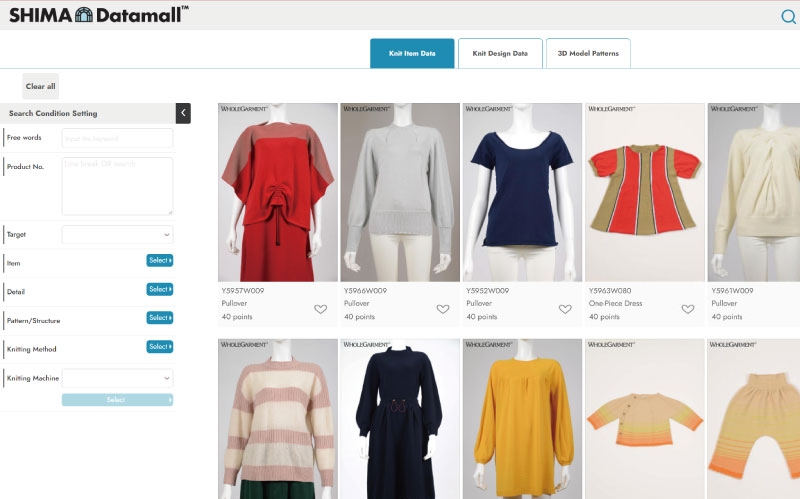

At SHIMA Datamall™, registered users can purchase and download knitting data for original knit samples including WHOLEGARMENT® items.

We can tailor solutions to fit each customer's requirements.

Please feel free to contact us.

TOP>WHOLEGARMENT®>WHOLEGARMENT® Business